CG1500 Single Level

1 PS + Falcon F16V3

Components in Design

Mounting Hardware Required (Details)

- 4x - #6 Self Tapping 1/2 in

- 4x - M4 PS Screw

- 4x - 4-40 Standoff

- 4x - 4-40 K Lock Nut

- 4x - 4-40 PCB Screw

About This Design

Simple, sturdy, and customizable

So your new to the Christmas Light game, you ordered your CG1500 and when it arrives you scratch your head wondering how in the heck the power supply will mount. We've all been there, and the answer is simple - you buy a mounting plate. Now we have some really cool mounting plates for the CG1500 like our Standard Double Decker, or our Double Decker Full Size but maybe you are a purist, maybe you dont' have many components to mount, or maybe you don't like fancy things.

So here it is, the basic Single Level CG1500 mounting plate - Only ours is fully customizable using the JDeation Designer!

Features

- Fully customizable component holes using the JDeation Designer

- Perfectly matched to mount to a CG1500 Enclosure

- ZipTie ports to secure wires to plate

- Plate Dimensions: 9.6in x 9.6in

Jdeation Featured Design

Design ID : MUDSYJAZ

Designer : jchancel

Components in Design

Mounting Hardware Required (Details)

- 4x - #6 Self Tapping 1/2 in

- 4x - M4 PS Screw

- 4x - 4-40 Standoff

- 4x - 4-40 K Lock Nut

- 4x - 4-40 PCB Screw

Works With (Sold Seperately)

DIY Build & Assembly Instructions

Assembly instructions for - CG1500 Single Level

All of the JDeation designs are customizable using the JDeation Designer

View our detailed walkthrough video for instructions on how to use the JDeation Designer

The following pieces of hardware are required for assembly of Mounting Plate.

Most parts are available at home depot - all are available online.

- Qty: 4 - #6 Self Tapping 1/2 in

- Qty: 4 - M4 PS Screw

- Qty: 4 - 4-40 Standoff

- Qty: 4 - 4-40 K Lock Nut

- Qty: 4 - 4-40 PCB Screw

The following plate fabrication instructions serve are general documentation for all mounting plate designs.

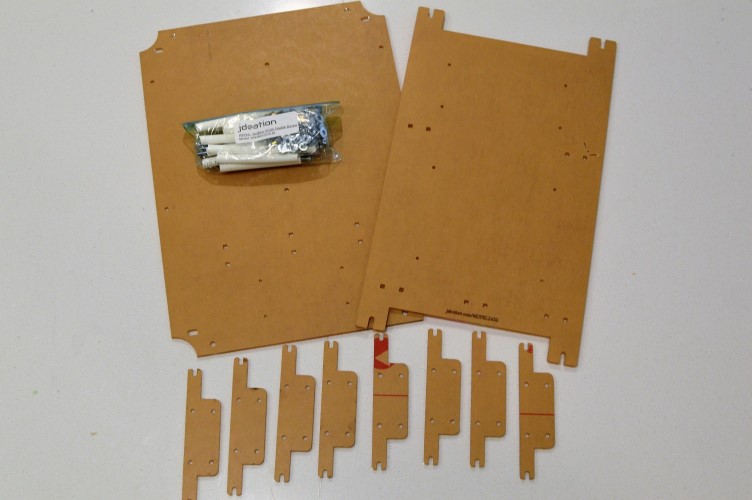

Step 1: Acquire Material

Acquire material to make your plates. Plastic or wood are good choices. The bellow instructions use 5mm plywood which was purchased from a local home depot. The material you choose MUST be 5mm or less in thickness.

Step 2: Print Design To Scale

Print your design on your home paper printer to scale.

On your design, click the download button and select PDF (Print). You must open the PDF in Adobe Reader to get the advanced print functions. Do not open the PDF in your browser. From the Adobe Reader print dialog box, select the following options.

Image of design printed to scale:

Step 3: Tape Design Together

Cut and Tape your designs together. Use the Adobe cross marks to align paper perfectly. It is important to spend time on this step and get alignment correct as a misaligned tape job will interfere with hole placements on layout.

Step 4: Apply Glue

Apply Gluestick to back of paper. We have had good success with repositionable glue sticks.

Step 5: Stick Design to Material

Apply paper design to wood. Line up two edges of design with two edges of wood if possible to reduce cutting.

Step 6: Drill Holes

Drill the black circles on the design. The following size drill bits are recommended. Also while not necessary it is recommended to use a brad point drill bit as it allows greater precision due to its sharp point on tip.

| Screw Size | Drill Size | Typical uses |

|---|---|---|

| 4/40 | 1/8" | Component standoffs |

| #6 | 5/32" | Self tapping screws for mounting to enclosure |

| #8 | 3/16" | 3" and 4" Bolts for P.S. and Shelves |

| #10 | 7/32" | 6" Bolts for P.S. and Shelves |

NOTE: All Black lines on design are cut or drill lines. Red lines are just for helping create the design and for information useful to assembly

Step 7: Cut Out Design

Use a Jig Saw to cut out the straight black lines.

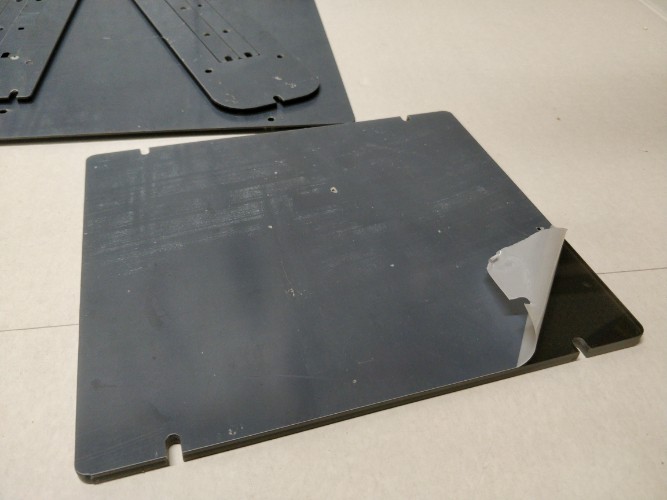

Step 1: Remove Protective Film

Remove plastic or paper film from both sides of acrylic or wood. Its much easier to do this now than after assembly.

NOTE: Occasionally the fabrication process will remove one or both sides. If you can see through the acrylic clearly then the film is gone.

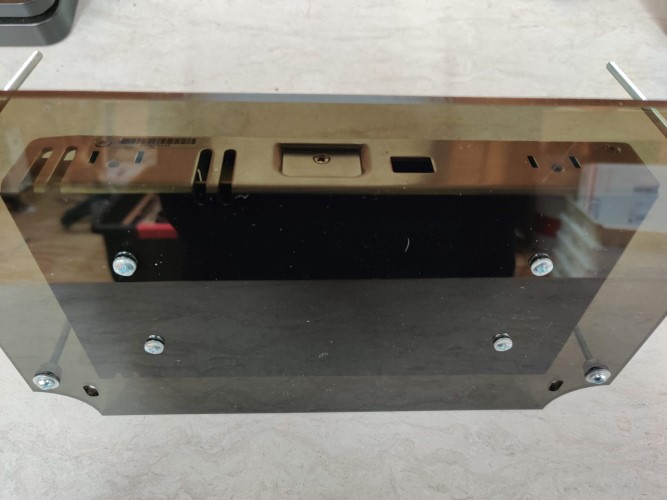

Step 2: Attach Power Supply To Bottom Plate

Depending on the design, power supplies are either attached via mounting brackets, or screwed directly to the bottom plate. If your design requires the power supplies to be screwed to the bottom plate, attach them now using M3 or M4 screws.

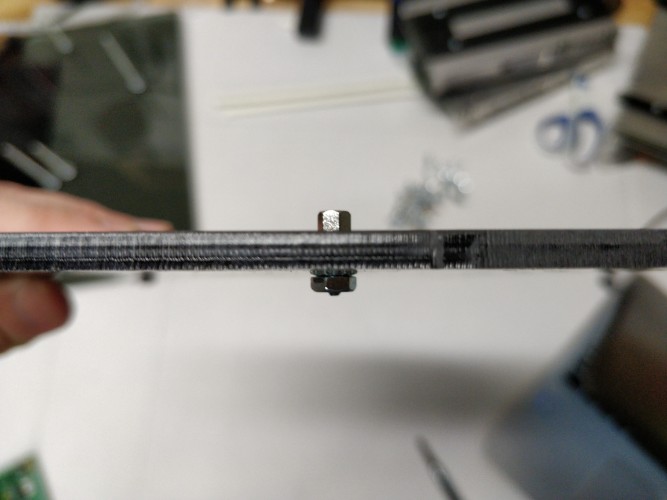

Step 4: Attach 4/40 Standoffs

Attach 4/40 standoffs and k-nuts to smallest holes. No washer is needed.

WARNING: DO NOT OVERTIGHTEN

Step 5: Attach Components

Attach components to the standoff. No washer is needed.

Step 6: Insert Plate into Enclosure

Use self tapping screws to attach mounting plate to the enclosure. Holes should be medium size and in each corner of the mounting plate.

Step 9: Wire It Up

Wire it up and make it fancy.

Few tips:

- Don’t tin your wires if inserting them into a screw down clamp. Solder will expand slightly and loosen the clamp.

- Use fuse between power supplies and controllers. A lose connection could cause an arc and if unfused could damage your power supply or your controller and potentially cause a fire.

- Make sure you use appropriate guage wire for the amperage you plan on needing. Small guage wire on high loads can cause greater voltage loss and in extreme cases start a fire.

View our timelapse of a JDeation Enclosure being wired up.

Step 10: Post Your Pics

Post a picture of your killer new build to facebook - make sure you tag JDeation Designer!

Use our contact page if you require assistance with your build.

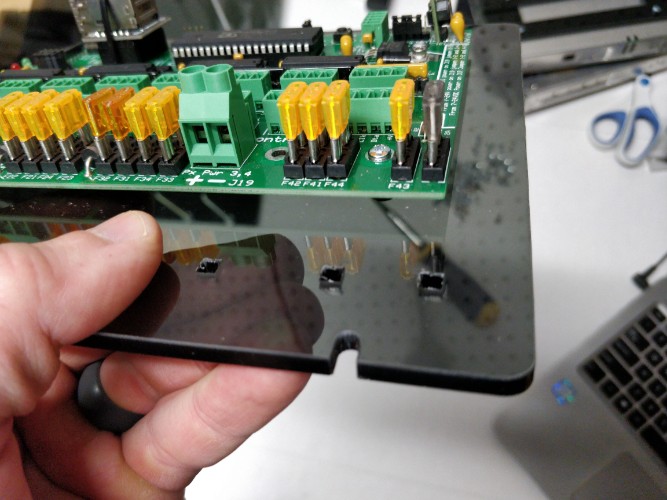

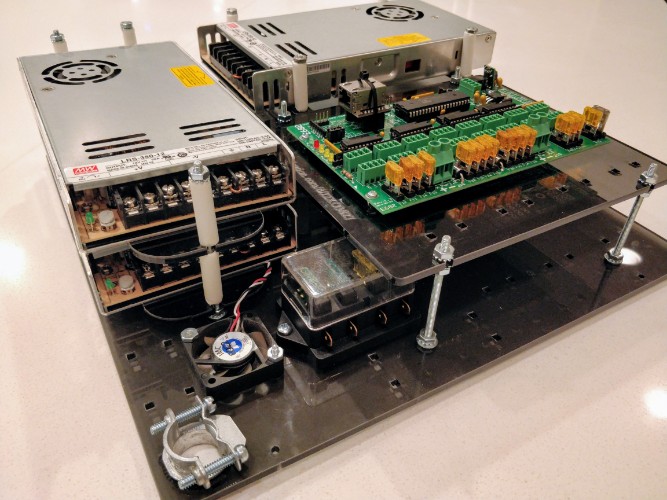

Finished Build (outside of case)

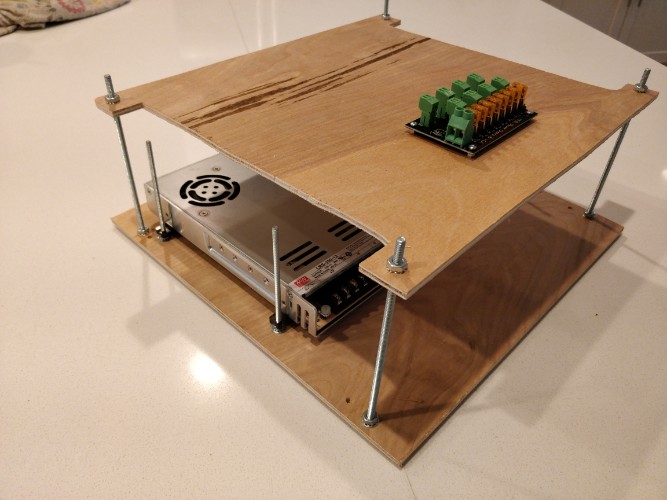

Finished Build with wood plates (outside of case)

Download

Download  Edit

Edit